Welcome to Celtic Water Solutions

Celtic Water Solutions (CWS) is a leading provider of water treatment and hygiene solutions, offering a broad portfolio of products, services and expertise to support residential, commercial, and industrial customers. For the last 20 years, we’ve been helping homeowners & businesses experience the benefits of filtered and purified water.

Our commitment to quality products and ongoing service has garnered us the trust of over 50,000 satisfied customers across Ireland.

We are a proud member of the Culligan Group, the world-leading provider of innovative and sustainable water solutions.

Latest News

Celtic Water Solutions Rebranding To Culligan Consumer Products (Ireland) Ltd. Read more...

Choose Water Filtration For

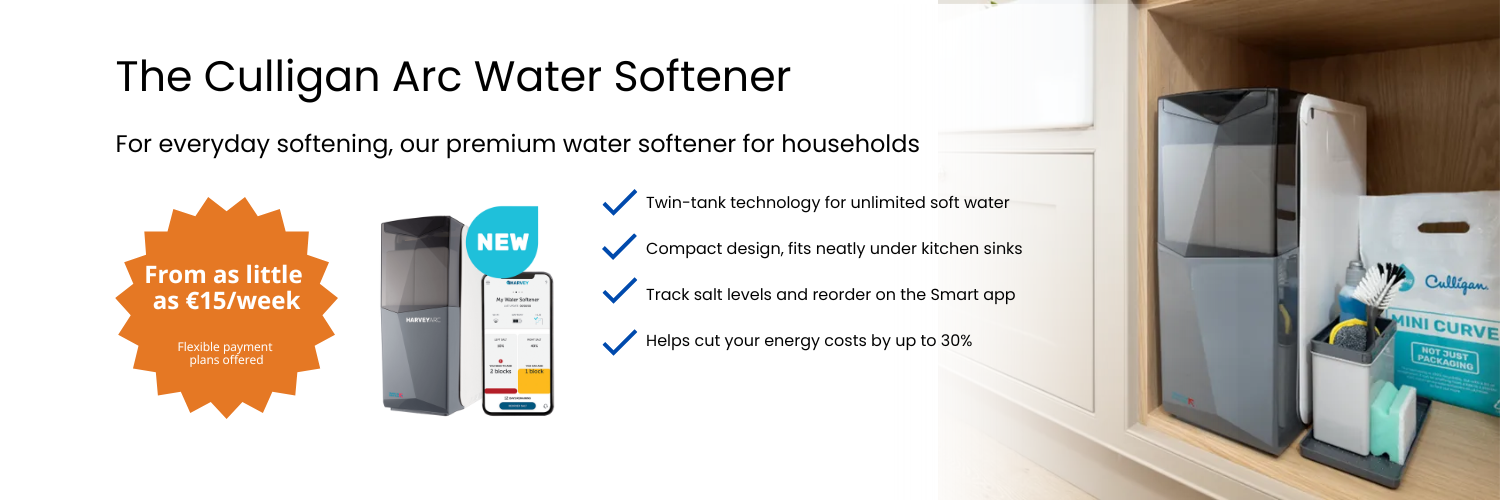

Enjoy a Limescale Free Home

With a CWS Water Softener in your home, everything that involves water gets better. From softer skin & shinier hair to long-lasting appliances, enjoy the benefits of soft water throughout your house. With any of our water softening systems, get more out of your water-using appliances while spending less on energy and cleaning products.

Our water softeners are designed to greatly remove hard water deposits & prevent limescale buildup. No matter the size of your home or your water usage, CWS has a water softener system to meet your needs.

Healthy & Great Tasting Drinking Water

CWS isn’t just about soft water – we want to make your water taste better too. Our drinking water systems are an economical & environmently-friendly way to reduce the unwanted contaminants found in tap water & deliver better tasting water for your whole family. Once you taste our water, we are confident you’ll never go back.

From a basic water filter all the way to multiple-stage RO systems, we can supply you with a filtration system that will fit your needs & budget.

Plastic Pledge

Every day we remind ourselves that so much can be done to protect our planet.

We are committed to reducing plastic waste and helping Ireland to play its part in achieving the goals set out in the EU Circular Economy Package.

We have updated our Privacy Notice. These changes are designed to provide greater clarity on how we use your personal information and to consolidate previously separate EU and rest-of-world notices into a single document.